OEM brake discs

OEM brake discs

BRED FROM THE CIRCUIT, MADE FOR THE ROAD – Every PFC disc is manufactured with the same process and testing conditions as our championship-winning race discs.

PFC DOUBLES THE LIFE, AND BEATS THE COST – PFC brake pads and discs double the pad and disc life. This results in lower maintenance costs and lower fuel consumption, yielding significant cost savings.

What sets PFC apart?

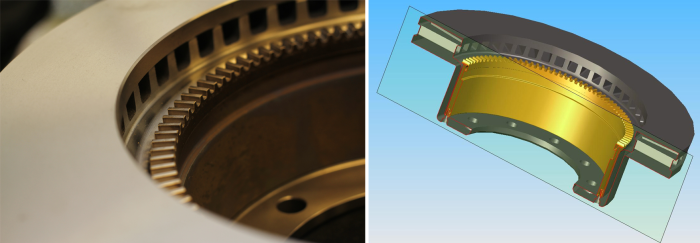

BEST DESIGN – PFC’s disc mounting designs minimise thermal deformation, reducing drag and eliminating thermal judder.

BEST DESIGN – PFC’s disc mounting designs minimise thermal deformation, reducing drag and eliminating thermal judder.

BEST MATERIALS – Custom developed highly-alloyed friction materials deliver superior performance at high temperatures.

BEST PROCESS CAPABILITY – PFC’s custom-designed machining centres are the most capable in the world

» Six Sigma Capable

GUARANTEED OEM QUALITY – PFC’s unparalleled design and machining capabilities mean ZERO ISSUES for the OEM brake engineer. PFC is the only machining centre can achieve the tightest tolerance specifications statistically allowing them to continually meet and exceed OEM design verification plans.

Direct Drive uses a saddle bobbin as part of the mounting

Direct Drive V2 is an integral drive in hat system and is a second generation disc mounting system designed to enhance the Z-Rated Big Brake kits by reducing the number of components and overall disc assembly weight.

Direct Drive V3 is the very latest generation mounting system that uses a spiral locking ring that connects the disc to the hat. This allows much faster fitting without the need for tools or fixings, and producing even less overall weight.